We produce a wide range of tanks, starting from small tanks of liquids and food products with a capacity below 1000l, through structures equipped with heating, cooling, washing systems, mixers and filters, to large tanks with capacity reaching several hundred m3.

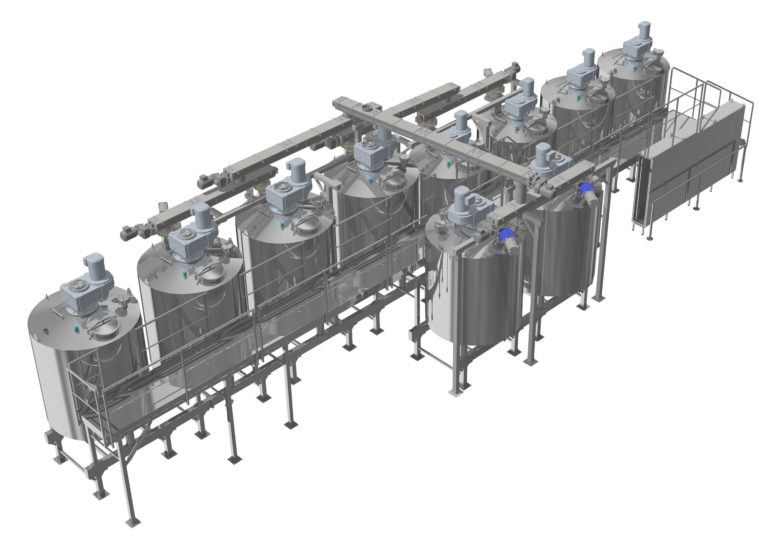

We produce complete transmission sets consisting of many interconnected devices. Very often we expand the existing infrastructure at the production plants of our Customers. We offer storage tanks as well as constructions equipped with various types of high and slow-running mixers with shape and speed adapted to the type of product mixed.

A well-designed and manufactured mixer often determines the success of the entire production process, so the geometry and type of the mixer are carefully selected by our engineers according to the production process in which they are used. We use vane, frame, anchor, rotor, turbine, worm, belt mixers as well as stirrers equipped with product scrapers and collectors.

The basic material used in the construction of our tanks is stainless steel AISI 304 (1.4301) and AISI 316 (1.4401). Depending on the application, we use steel grades with different carbon content and alloying additives. We produce tanks in multi-layer systems, also in the PILLOW-PLATE technology and tanks insulated with mineral wool.

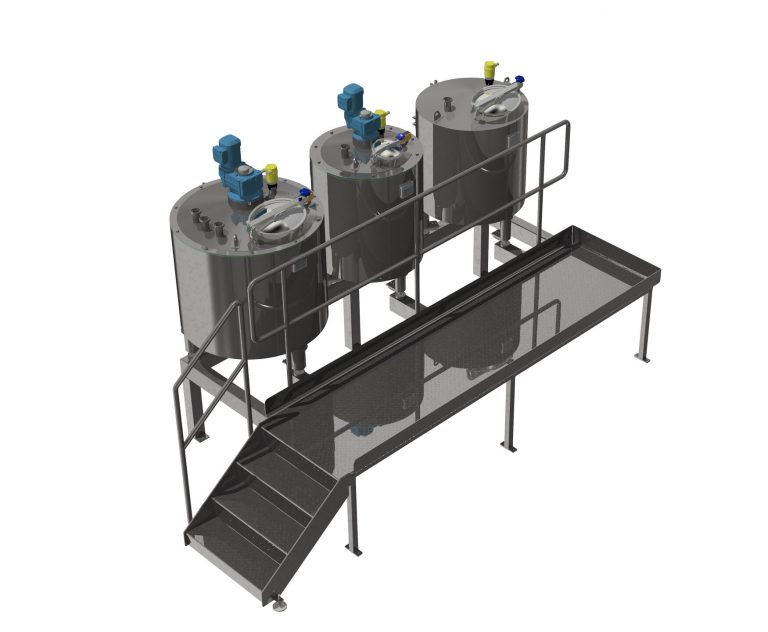

In order to adapt to the needs of our Customers, we use various variants of the location of mixers and their drives. We offer tanks with upper, lateral, oblique and bottom agitators. Our tanks have a wide range of operating temperatures, and careful selection of all parameters results in devices matched perfectly to process conditions, guaranteeing safe and efficient processing of a wide range of products.In case of any doubts, we assist our Customers in making the right choice.

Our offer includes:

- Our offer includes:

- Mobile tanks

- Storage tanks

- Process tanks

- Aseptic tanks

- Brewing tanks

- Wine tanks

- Process water tanks

The design of our tanks

Many years of experience in the industry have taught us that food industry machines should not have elements that cause accumulation of food products.

When developing our tanks we make sure that there are no such spots both inside and outside, while the design of our products itself meets the hygienic requirements of the food industry and enables quick and easy cleaning.

We also manufacture tanks equipped with various washing systems, including the CIP system, washing nozzles, etc.

An important part of any tank is its equipment. At Customer’s request we offer equipping our tanks with various sensors, e.g. level, temperature and weight sensors. We also take care of operational safety by installing limit switches and safety grilles. All tanks equipped with drives are so constructed that, in an event of a failure, the oil contained in the engine does not penetrate into the tank. We often integrate our tanks with existing transmission systems – then all product connections and heating elements are located in a way that enables quick and easy connection to existing installations.